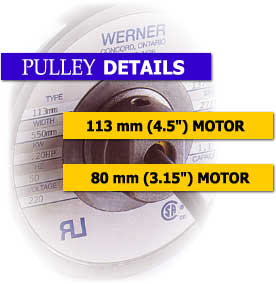

Werner Motor Company

Werner Motor Company

The permanent split-capacitor AC motor is designed with a

low operating temperature without sacrificing

starting and running torque.

Single-phase motors are available at either 115 volts

(60 Hz), or 220 volts (50Hz and 60 Hz). Other voltages

and frequencies in single-phase motors are also available.

Electrical stators are insulated as NEMA class B and require

an externally mounted capacitor.

All motorized pulleys are equipped with a resettable

internal thermal overload fuse that will disconnect

power if motor windings reach excessively high temperatures.

This protection is the best safeguard available against motor

failure. Motors are reversible and have a duty-cycle

of 30 starts/stops per minute. |

Our motors are capable of driving belts for small part conveyors |

The planetary gear system, which has

either two or three stages of reduction, is molded of high

precision injection-molded acetal plastic to ensure the lowest

possible noise level. This gear system is designed

to withstand overload. Various gear combinations generate

fixed belt speeds.

The motor cylinder tube

has a trapezoidal crown machined for optimum belt traction

and tracking, in accordance with specifications of most conveyor

belt manufacturers. A coating of Rust-Ban is

applied to the tube to protect it against corrosion during

transportation and storage.

|

|

The motorized pulleys contain Esso NUTO H68 oil or an equivalent,

which lubricates all internal moving parts to cool the electrical

motor. For this reason, the the unit should be mounted horizontally.

Since the belt helps to remove heat from the drive pulley, it should

not normally be operated without a belt. These pulleys never

require an oil change.

The Werner

patented oil agitator circulates the oil to distribute heat evenly

over the width of the pulley. This allows for easier belt tracking

and lower belt temperatures.

Spring-loaded oil

seals, running on a precision centreless ground shaft, prevent

entry of dust, dirt and moisture, while preventing

loss or contamination of oil. In addition, rubber-sealed

ball bearings and end caps provide further protection. As a result,

the unit is maintenance-free.

|